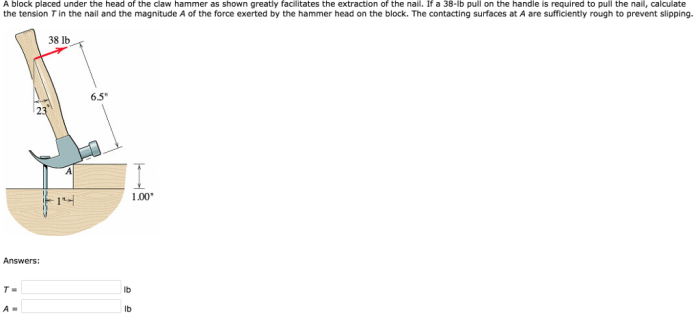

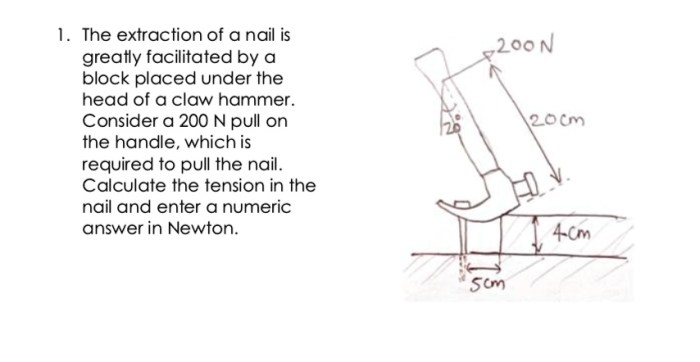

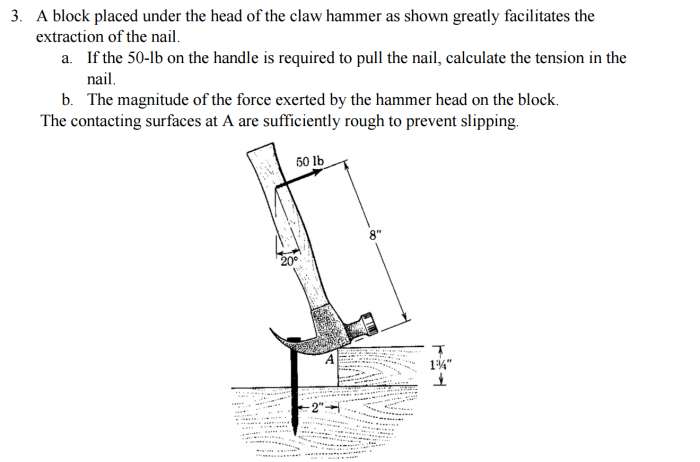

A block placed under the head of the claw hammer – The humble block placed under the head of a claw hammer is an often-overlooked yet indispensable tool that enhances functionality, safety, and versatility in various industries. This article delves into the historical significance, functional benefits, material considerations, design variations, safety considerations, alternative methods, applications, and maintenance techniques associated with this unassuming yet essential tool.

Historical Significance

The practice of placing a block under the head of a claw hammer has its roots in ancient times. In early civilizations, blacksmiths and other craftsmen used blocks to enhance the leverage and stability of their hammers, enabling them to perform tasks with greater precision and efficiency.

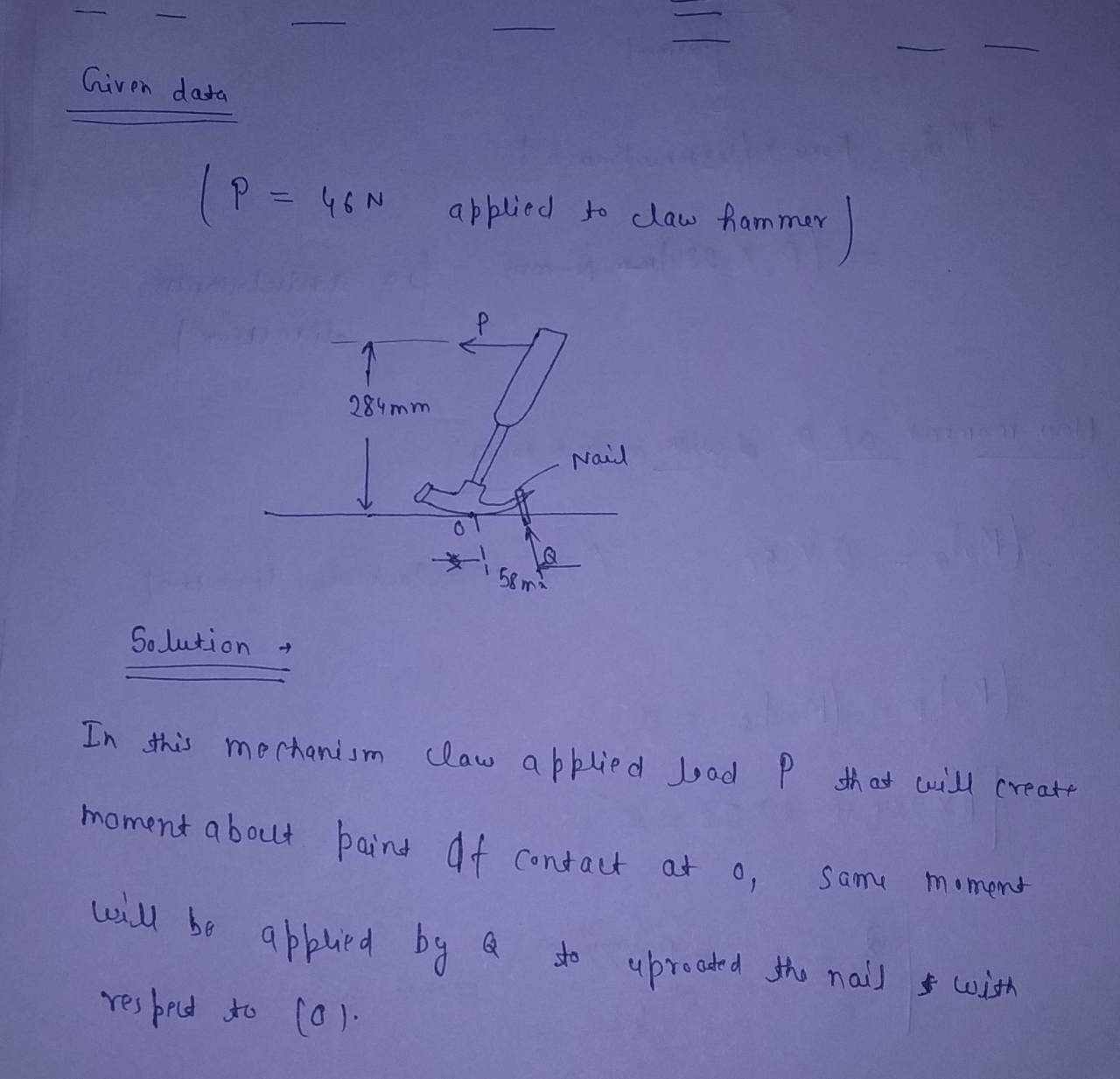

Functional Benefits: A Block Placed Under The Head Of The Claw Hammer

Using a block with a claw hammer offers several functional benefits. Firstly, it provides increased leverage, allowing users to exert greater force with less effort. This is particularly useful when driving nails into hard or dense materials.

Material Considerations

The effectiveness of a block used with a claw hammer depends on the material it is made from. Common materials include wood, rubber, and steel.

- Wood: Wooden blocks are lightweight and provide a good balance of leverage and cushioning.

- Rubber: Rubber blocks are highly durable and can withstand repeated impacts. They also provide excellent grip and prevent the hammer from slipping.

- Steel: Steel blocks are the most durable and can handle the heaviest hammering tasks. However, they can be heavier and more expensive than other materials.

Design Variations

Blocks used with claw hammers come in a variety of designs to cater to specific applications and user preferences.

- Rectangular blocks: These are the most common type and provide a stable and versatile base for the hammer.

- Wedge-shaped blocks: These blocks are designed to fit into tight spaces and provide a more secure grip on the hammer.

- Contoured blocks: These blocks are designed to fit the curvature of the hammer head, providing maximum contact and stability.

Safety Considerations

Using a block with a claw hammer requires certain safety precautions. Improper usage can lead to injuries or damage to the hammer.

- Ensure the block is securely placed: The block should be positioned under the head of the hammer and held firmly in place to prevent it from slipping or moving during use.

- Use the correct size block: The block should be large enough to provide adequate support for the hammer and prevent it from damaging the work surface.

- Inspect the block regularly: Check the block for cracks or damage before each use. Replace any damaged blocks immediately.

Alternatives to Using a Block, A block placed under the head of the claw hammer

While a block is a common and effective tool for enhancing the functionality of a claw hammer, there are alternative methods that can achieve similar results.

- Nail set: A nail set is a specialized tool designed for driving nails below the surface of the wood. It provides greater precision and control than a claw hammer alone.

- Magnetic hammer: Magnetic hammers have a built-in magnet that holds nails in place, eliminating the need for a block.

Applications in Different Industries

Blocks used with claw hammers find applications in a wide range of industries.

- Construction: In construction, blocks are used to drive nails into wood framing, drywall, and other materials.

- Carpentry: Carpenters use blocks to create joints, assemble furniture, and perform other woodworking tasks.

- Automotive repair: Mechanics use blocks to remove bolts, pry open panels, and perform other automotive repairs.

Maintenance and Care

Proper maintenance of a block used with a claw hammer is essential to ensure its longevity.

- Clean the block regularly: Remove any dirt or debris from the block using a damp cloth.

- Inspect the block for damage: Check the block for cracks or damage before each use. Replace any damaged blocks immediately.

- Store the block in a dry place: Store the block in a dry place to prevent it from warping or rotting.

Top FAQs

What is the primary purpose of using a block under a claw hammer?

A block placed under the head of a claw hammer serves multiple purposes, including enhancing leverage for increased force, providing stability to prevent hammer slippage, and protecting surfaces from damage during hammering.

What materials are commonly used to make blocks for claw hammers?

Blocks for claw hammers are typically made from materials such as wood, rubber, plastic, or metal, each offering unique advantages in terms of weight, durability, and impact resistance.

Are there different designs of blocks for claw hammers?

Yes, blocks for claw hammers come in various designs, including square, rectangular, round, or contoured shapes, to accommodate different hammer sizes, user preferences, and specific applications.

What safety precautions should be observed when using a block with a claw hammer?

When using a block with a claw hammer, it is crucial to ensure the block is securely positioned, use the appropriate size and material for the task, and wear appropriate safety gear to prevent injuries or damage to the hammer.